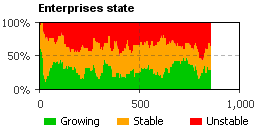

If for this simplified process it is already possible to make several interesting analyzes, imagine for a model of a complex production line, in which the manager needs to evaluate the impact of a modification and present the results of this modification in a meeting with directors. It is possible to create parameters not only related to the process itself (raw material supply/transport capacity, production capacity of a machine), but also parameters related to costs, for example. Eventually, the queue comes close to the 50 part limit, when a change is quickly made to the machineProduction parameter, reducing the production time to consume excess parts in the queue. The size of the parts queue is the most visible result of changing the parameters. After the start of the simulation, observe the impact of the variation of the parameters in the production time distribution graph and in the graph that accompanies the number of parts that pass through the source and delay blocks. Through the slider controls, it is possible to modify the parameters previously defined for this process, within the permitted limits. O video abaixo mostra a gravação da simulação do processo modelado no Anylogic: Modify and observe the results through the graphs. There you go! Start the simulation with F5 and then click Play.ĭuring the simulation it is possible to adjust the parameter values within the pre-established limits. This is the interval that the slider control will allow the machineProduction parameter to vary. This parameter is of type integral, floating point, enum, or time stamp. Select the Link to: checkbox, and choose machineProduction from the list. Any logic state variables (if present) are also automatically checkpointed and. This is the range that the slider control will allow the sourceRawMaterial parameter to vary.ĭrag another Slider control, this time next to the machineProduction parameter, and name it as : slider_machineProduction. Select the Link to: checkbox, and choose sourceRawMaterial from the list. Set the name as: slider_sourceRawMaterial. Drag the Slider control next to the sourceRawMaterial parameter. For this, we will use the Controls palette. Select the block delay and set machineProduction to Delay time įinally, we will create the graphical interface controls that will allow us to modify the parameter values during the simulation. Select the source block and set sourceRawMaterial to Arrival rate Now we will link these parameters to the source and machine blocks created in the previous articles. Repeat steps 3 and 4 above for this parameter created.

Name it as: sourceRawMaterial ĭrag a new Parameter block next to the previous one, but this time name it as: machineProduction. Create startWaiting parameter of type double to store the time when the. Thus, we will be able to continue where we left off įrom the Agents palette, drag a Parameter block onto the work area. We will collect time statistics using AnyLogic analysis data objects and observe.

0 kommentar(er)

0 kommentar(er)